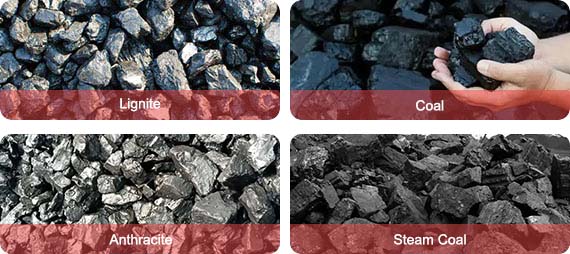

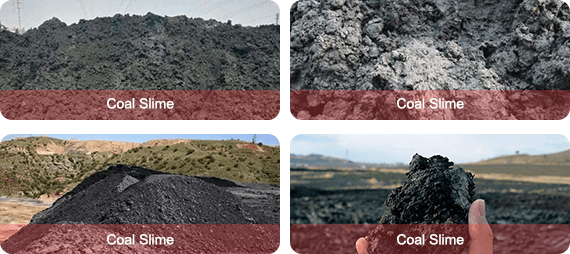

Coal dryer can be widely used for drying coal, coal slime, peat, sludge, raw coal, lignite, flotation clean coal, mixed clean coal and other coal industry materials.

| Product Standard(M) | Capacity(T/H) | Feed Moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 20-15% | 3KW |

| 1*10 | 1-5 | 30% | 20-15% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 20-15% | 11KW |

| 1.6*16 | 6-10 | 30% | 20-15% | 15KW |

| 1.8*16 | 8-15 | 30% | 20-15% | 18.5KW |

| 2*18 | 10-20 | 30% | 20-15% | 22KW |

| 2.2*18 | 12-25 | 30% | 20-15% | 30KW |

| 2.4*22 | 15-30 | 30% | 20-15% | 45KW |

| 2.6*24 | 18-35 | 30% | 20-15% | 55KW |

| 2.8*26 | 20-40 | 30% | 20-15% | 75KW |

| 3*28 | 25-50 | 30% | 20-15% | 90KW |

| 3.2*28 | 30-60 | 30% | 20-15% | 110KW |

| 3.4*30 | 35-70 | 30% | 20-15% | 132KW |

| 3.6*32 | 40-80 | 30% | 20-15% | 160KW |

| 3.8*32 | 50-100 | 30% | 20-15% | 185KW |

Gas furnace

Gas furnace

fluidized bed heater

fluidized bed heater

Chain grate stove

Chain grate stove

Pulverized coal combustion chamber

Pulverized coal combustion chamber

Combustion chamber + coal injection machine

Combustion chamber + coal injection machine

Coal grinding powder spraying machine

Coal grinding powder spraying machine