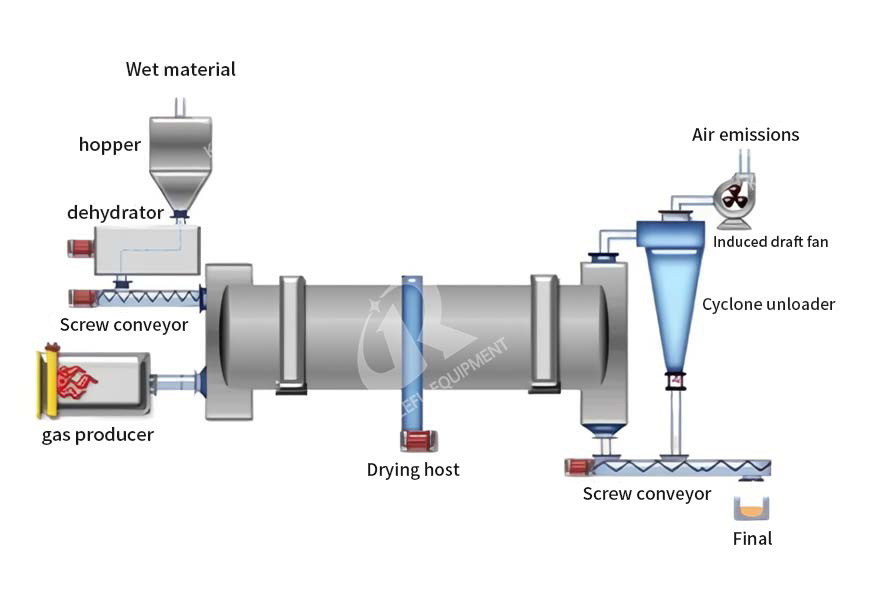

The material is shoveled by the loader to the feeding belt conveyor, fed into the drum screw propulsion device through the feeding belt conveyor, and then quickly guided to the inclined material lifting area through the large dip guide plate, and with the rotation of the drum and the inclination of the cylinder. It is lifted from the bottom of the cylinder to the top of the cylinder, forming the material curtain. And wet material at the same end into the drying drum of high temperature flue gas through the wet material to form conduction and convection heat exchange, preheat wet material and evaporate part of the water. At the same time, the temperature of the high temperature flue gas drops rapidly, and the preheated wet material enters the medium temperature drying stage, and most of the water is evaporated at this stage. With the repeated mixing and exchange of materials and flue gas, the materials are discharged from the drying drum until the heat balance is reached and the moisture requirements of the materials are met. After heat exchange, the tail gas containing a lot of water vapor and dust goes through the primary cyclone dust removal for coarse dust removal, and then through the secondary bag dust collector or wet dust collector for fine dust removal. The dust content of the purified tail gas meets the requirements of environmental protection standards and is discharged directly to form the whole drying process.

| product standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1-5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6-10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8-15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10-20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12-25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15-30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18-35 | 30% | 15%-1% | 55KW |

| 2.8*26 | 20-40 | 30% | 15%-1% | 75KW |

| 3*28 | 25-50 | 30% | 15%-1% | 90KW |

| 3.2*28 | 30-60 | 30% | 15%-1% | 110KW |

| 3.4*30 | 35-70 | 30% | 15%-1% | 132KW |

| 3.6*32 | 40-80 | 30% | 15%-1% | 160KW |

| 3.8*32 | 50-100 | 30% | 15%-1% | 185KW |