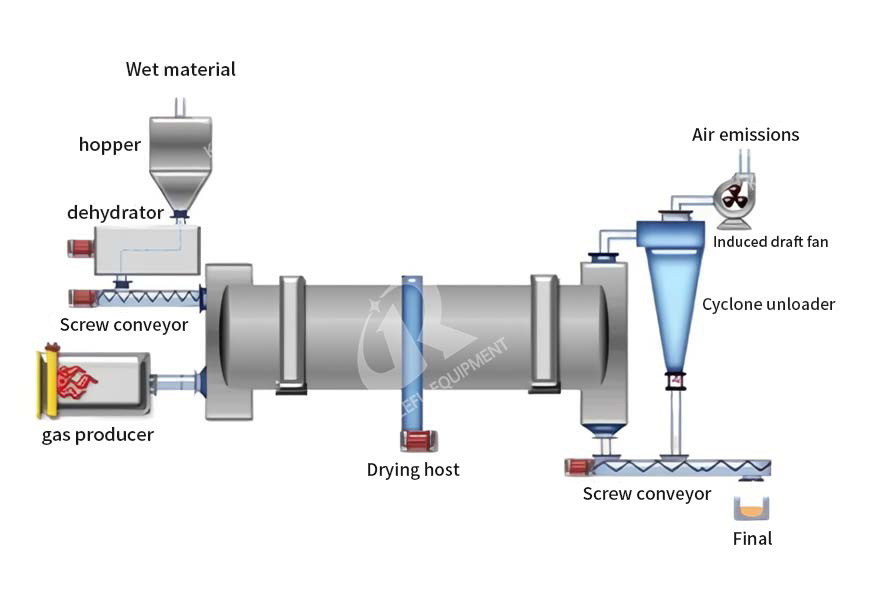

The materials can move through the cylinder and rotate in that,the wet materials fed into the cylinder from the upper place of one end ,and the heat source come into the cylind from either end,during the wet materials and hot air come through the cyinder,the moisture will be reduced,and the dry materials willcollected from the other side of the cylinder.

| Product Standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1—5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2_8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6_10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8—15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10—20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12—25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15—30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18—35 | 30% | 15%-1% | 55KW |