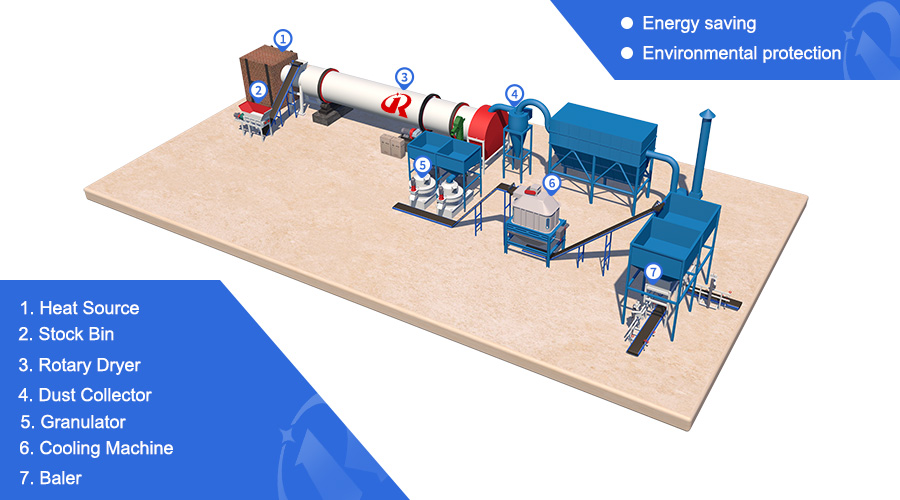

1

Good sealing and high thermal efficiencyInlet and outlet head adopts special seal to effectively reduce heat loss.

2

Wide application range, large processing capacityIt can be dried upstream or upstream. Therefore, it can be applied to the drying of certain heat-sensitive materials. The drying treatment of granular, fibrous, powdery and other loose materials with different specific gravity, particle size and water content can achieve good dehydration and drying effect.

3

High degree of automation, continuous productionThe dehydration and drying time can be adjusted according to the material properties and moisture requirements.

4

Seiko manufacturing, long service lifeHigh quality stainless steel plate refined, wear-resistant and durable.