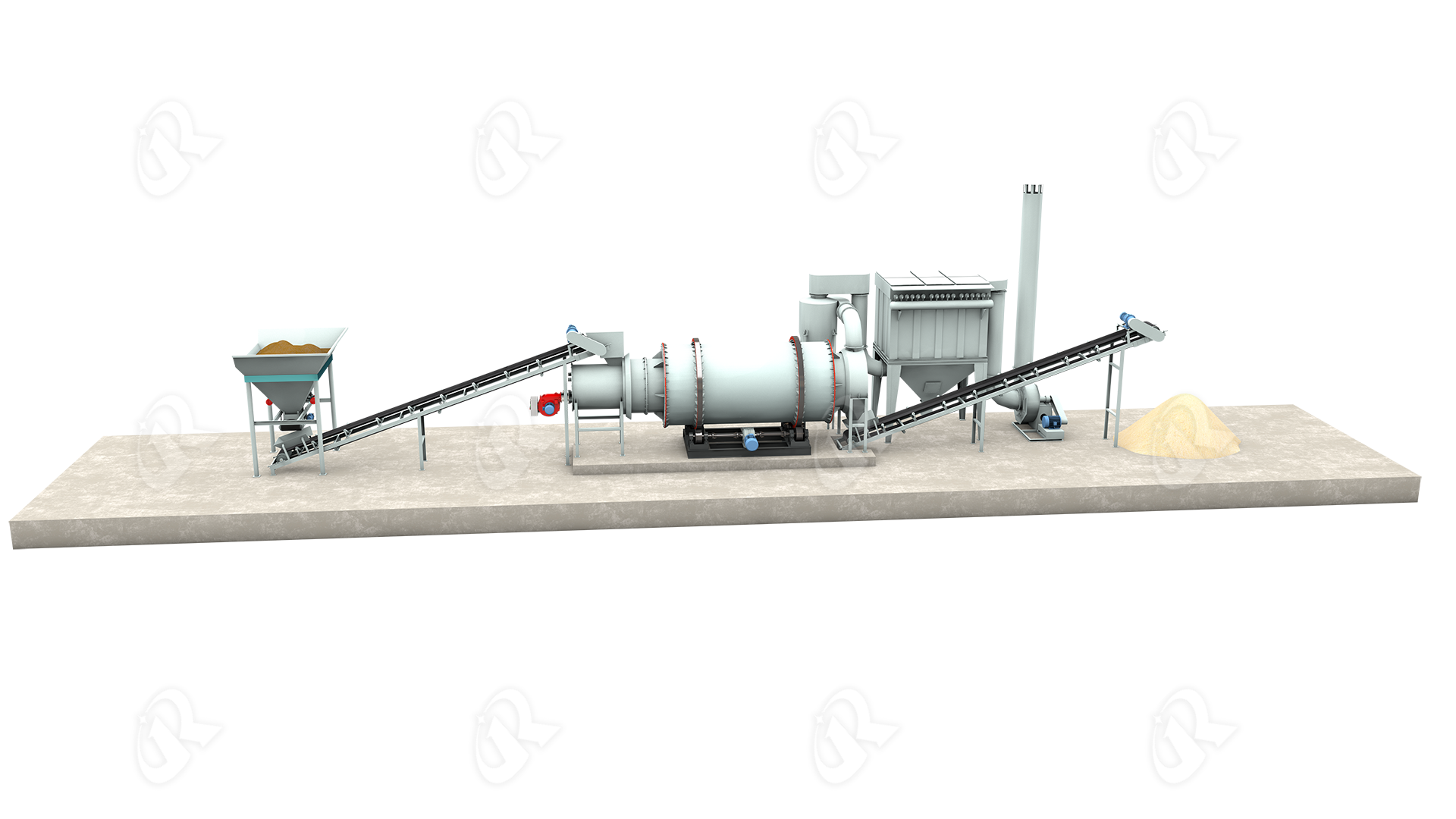

Three-cylinder dryer High-efficiency combined three-pass dryer is mainly used for drying granular materials.

such as yellow sand used in the dry mortar industry, various specifications of molding sand used in the foundry industry, blast furnace slag and other materials used in the building materials and cement industry.

Water slag, clay, slag, fly ash and other materials.

According to the final moisture content requirements of dried materials in different industries, the moisture content of dried materials can be below 1-0.5%.

The wet material into the inner cylinder of the feeding end, is quickly pushed to the spiral lifting plate by the spiral guide plate. With the rotation of the cylinder, the spiral lifting plates set up in three cylinders make the materials lifted, at the same time, the materials continue to roll, scatter and do longitudinal motion. At the same time the hot gas flow from the heat source successively enters the inner drum, the middle drum and the outer drum and to meet the material for a strong heat exchange. The thermal conductivity of metal plate is faster than that of materials, steel plate and lifting plate of cylinder of the first heat, then the heat by conduction and radiation transmitted to the material, the material is heated, when the temperature rises to the evaporation temperature, water vapor is separated from the material, discharged with the dust into the atmosphere, so as to achieve the purpose of drying materials.

| Specifications and Models | Handling Capacity (t/h) | Finished Product Moisture(%) | Power(KW) |

| KLF-TH1630 | 1-5 | <2±1 | 4 |

| KLF-TH2240 | 6-10 | <2±1 | 4 |

| KLF-TH2460 | 10-15 | <2±1 | 7.5 |

| KLF-TH2660 | 15-20 | <2±1 | 15 |

| KLF-TH2870 | 25-30 | <2±1 | 18.5 |

| KLF-TH3080 | 30-40 | <2±1 | 22 |

| KLF-TH3290 | 40-50 | <2±1 | 45 |

| KLF-TH3390 | 50-60 | <2±1 | 55 |

| KLF-TH3610 | 70-80 | <2±1 | 75 |

| The above parameters are for reference only. For more details, please contact customer service | |||