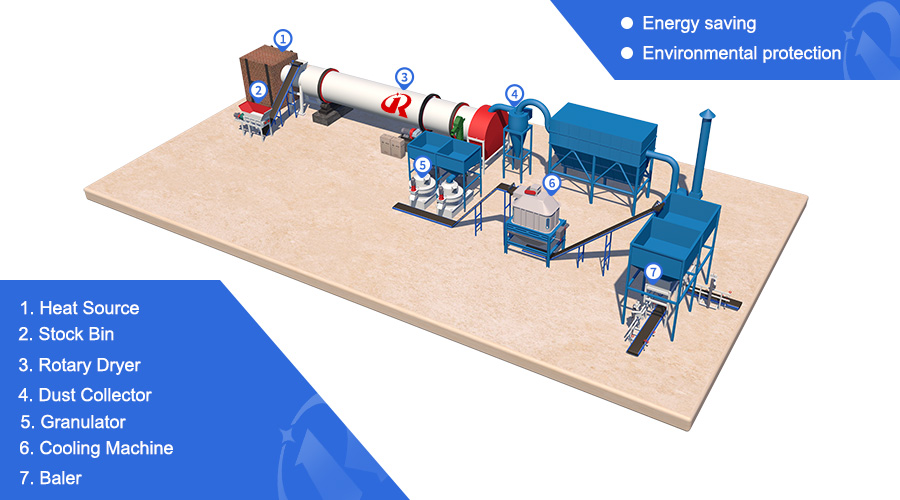

Grass Rotary Dyer

Grass rotary dryer has large output, high efficiency and energy saving, and covers a small area. It is especially suitable for drying grass and other high moisture materials when used together with clean hot blast stove. It can quickly dry the moisture of grass from 65-75% to 14-18% in one go. Compared with the ordinary dryer energy saving up to 30-50%, can save energy and drying costs.Grass rotary dryer is suitable for elephant grass, alfalfa grass, Timothy grass, leaf grass, leaf structure, straw, pitcher grass and other grass fast drying processing grass feed, according to the characteristics of each material, yield size, quality requirements, application requirements, cost control, automatic degree, site conditions, investment line to optimize the drying technology and equipment selection and configuration services.

12%(adjustable)

Output moisture