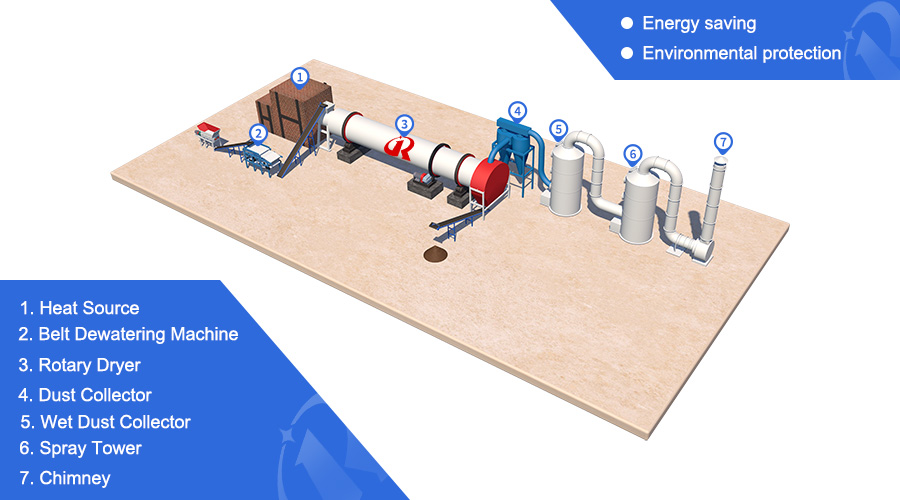

The complete set of cow dung rotary dryermainly is composed of the drum dryer, feed spiral, output spiral, pipeline,burning furnace, dust collector, airlock, air induced fan, electric control cabinet and other components.Humidity materials are conveyed from the feed screw directly into the dryer drum, raised by the drum wall panels repeatedly, and scattered by the crushing blow dispersion devices. Materials and the negative high-temp media are combined sufficiently to complete heat and mass transfer process. As the result of the drum wind angle and the induced air, the feed materials move slowly, and discharged from the spiral after drying, the exhaust gas handled by the dust precipitator, venting to the atmosphere.

| Product Standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1-5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6-10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8-15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10-20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12-25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15-30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18-35 | 30% | 15%-1% | 55KW |