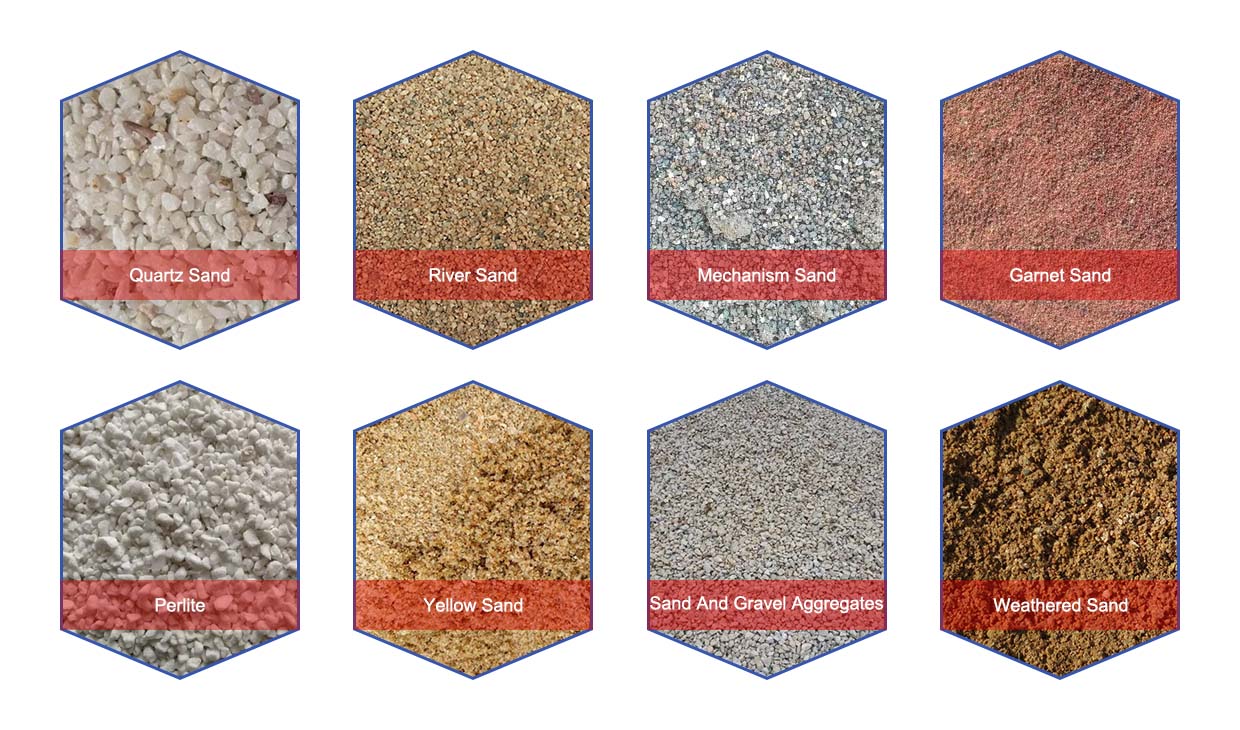

Suitable for drying sand, such as silica sand, mineral sand,frac sand, quartz sand, river sand, yellow sand, sea sand, garnet sand, machine-made sand, dry powder mortar, water slag, mountain sand, weathered sand, etc. After drying, it can be used in construction and cement products, interior decoration and engineering construction, casting sand, concrete ingredients, building insulation mortar, sewage treatment, artificial beaches, etc.

| Specifications And Models | Handling Capacity Drying Sand(T/H) | Finished Product Moisture(%) | Power(KW) |

| KLF-TH1216 | 1-3 | <2±1 | 4 |

| KLF-TH1630 | 3-5 | <2±1 | 4 |

| KLF-TH2240 | 8-10 | <2±1 | 4 |

| KLF-TH2460 | 10-15 | <2±1 | 7.5 |

| KLF-TH2660 | 15-20 | <2±1 | 15 |

| KLF-TH2870 | 25-30 | <2±1 | 18.5 |

| KLF-TH3080 | 30-40 | <2±1 | 22 |

| KLF-TH3290 | 40-50 | <2±1 | 45 |

| KLF-TH3390 | 50-60 | <2±1 | 55 |

| KLF-TH3610 | 70-80 | <2±1 | 75 |

| The Above Parameters Are For Reference Only. For More Details, Please Contact Customer Service | |||