1

✅ CE & ISO 9001 Certified QualityRigorously tested drying systems meeting European safety & quality standards – guaranteed reliability for demanding operations

2

🔥 Precision Indirect Heating TechPatented flight design ensures uniform 360° material agitation, reducing moisture content by up to 70% faster than conventional dryers while preventing combustion risks

3

🛡️ Heavy-Duty Abrasion Resistance3x reinforced inner lining and military-grade steel construction withstands abrasive biomass materials – extending service life by 40%

4

📊 Smart Control IntegrationIoT-ready control systems with real-time moisture monitoring (±0.5% accuracy) and automated heat adjustment – optimize energy consumption by 25%

5

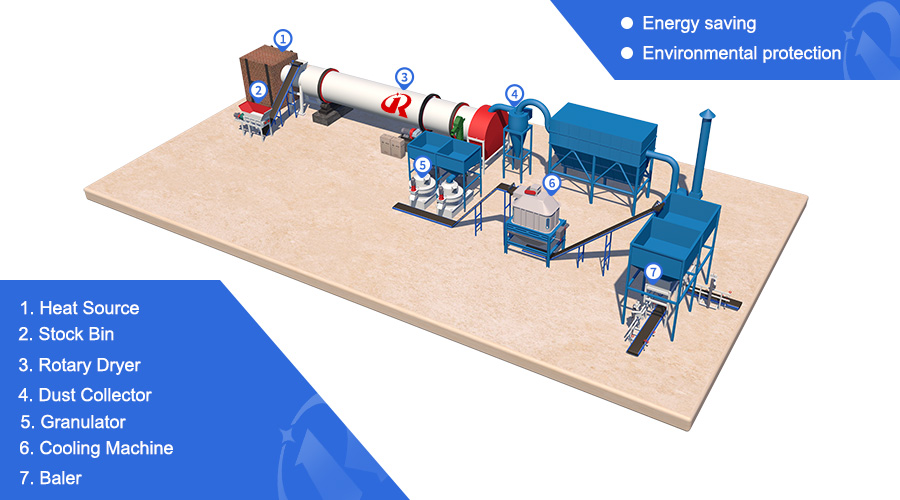

🌱 Turnkey Production SolutionsFrom feeding systems to packaging: We engineer, install, and commission complete straw processing lines – operational within 30 days

6

📈Adjustable ParametersDrum rotation speed, temperature, airflow, and residence time can be adjusted to optimize drying for specific materials and target moisture levels.