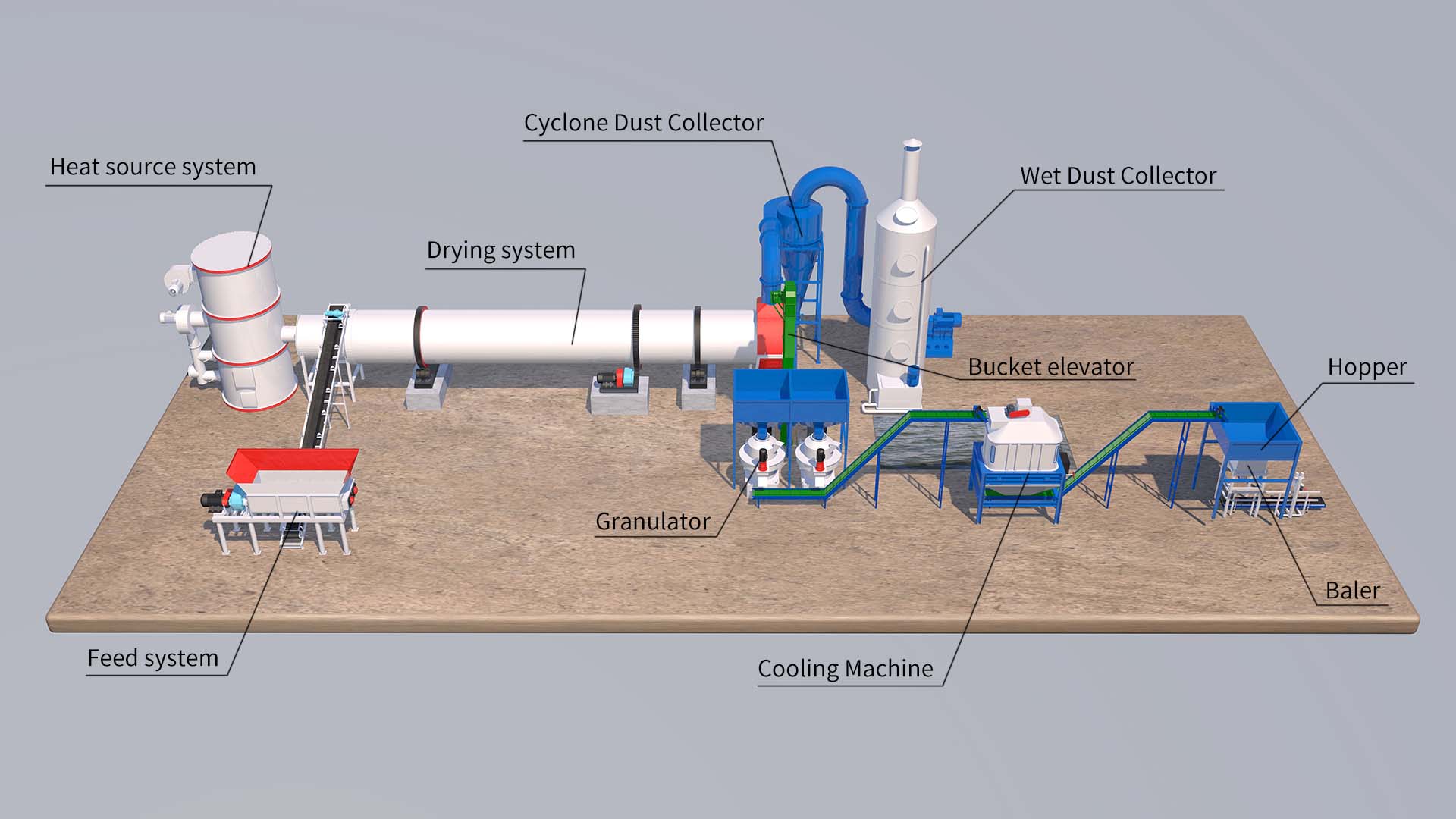

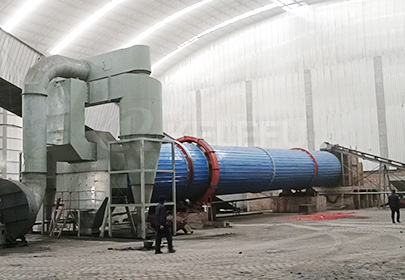

Biomass fuel dryer is suitable for wood chips, sawdust,chips,Corn Cob, wood chips, shavings, barley straw.After crushing, drying and granulating, biomass can be turned into biomass fuel, which is a clean energy source that can be directly burned and used. It has the advantages of high calorific value, cleanliness, no pollution, and high added value.

In most cases, biomass (bark, wood chips, sawdust) has to be dried before being used in pelleting, briquetting, incineration, and gasification.

By reducing the water content, the calorific value increases from 2 kWh/kg to approximately 4.5 kWh/kg. This cuts the transport and storage costs and creates the ideal conditions for direct firing or optimum pelletizing properties, both for industrial and for high-grade wood pellets. As a result of the drying process, less fuel is required to generate energy, which also reduces the emissions caused by the firing process.

There are several reasons why biomass needs to be dried:

- Increase energy density: The moisture content in biomass is high, and drying can remove the moisture, thereby increasing the energy density of biomass and making it easier to store and transport.

- Improve combustion efficiency: The moisture in biomass will reduce combustion efficiency, and drying can remove the moisture, thereby improving combustion efficiency and reducing energy waste.

- Reduce pollution emissions: The moisture in biomass will produce a large amount of water vapor and pollutants during the combustion process. Drying can remove the moisture, thereby reducing pollution emissions.

- Improve the quality of biomass: Drying can remove impurities and harmful substances from biomass, thereby improving the quality of biomass and making it more suitable for energy production and other uses.