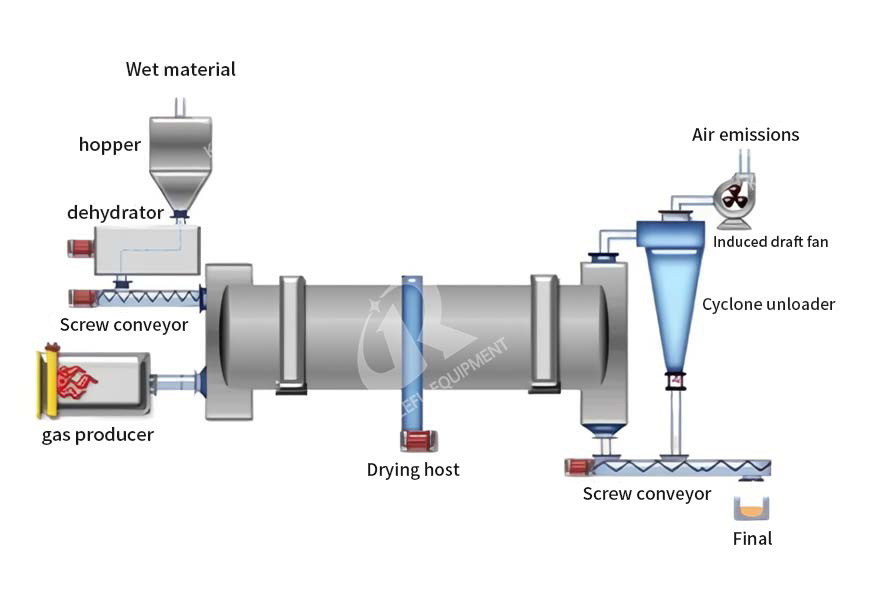

The kaolin rotary dryer is a rotating cylinder slightly inclined from the horizontal line. The material is added from the higher end, the heat carrier enters from the lower end, and comes into countercurrent contact with the material, and the heat carrier and the material flow into the cylinder together. As the cylinder rotates, the material moves to the lower end under the effect of gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly obtained by the heating medium, so that the wet material is dried, and then sent out by a belt conveyor or a screw conveyor at the discharge end.

| product standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1-5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6-10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8-15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10-20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12-25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15-30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18-35 | 30% | 15%-1% | 55KW |

| 2.8*26 | 20-40 | 30% | 15%-1% | 75KW |

| 3*28 | 25-50 | 30% | 15%-1% | 90KW |

| 3.2*28 | 30-60 | 30% | 15%-1% | 110KW |

| 3.4*30 | 35-70 | 30% | 15%-1% | 132KW |

| 3.6*32 | 40-80 | 30% | 15%-1% | 160KW |

| 3.8*32 | 50-100 | 30% | 15%-1% | 185KW |