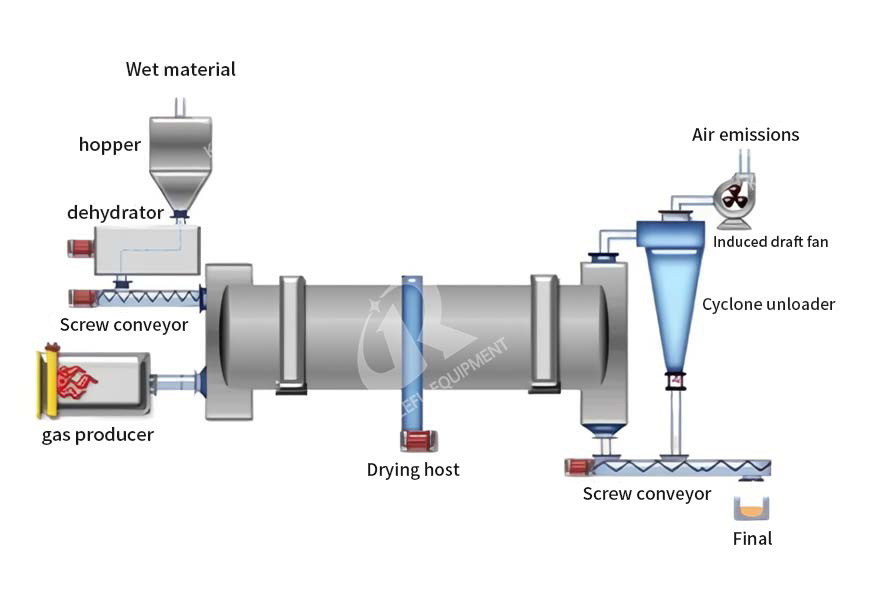

adopts direct flow type of heating with heat soure from firing unit. The material to be dried is pushed back immindiately by spiral board when enters the shell from feeding tank and feeding chute. Because the dryer is installed in slope, material flows to the back end under gravity and rotation force, meanwhile, it is lifted by board repeatedly and thrown down accordingly, which make the material form even curtain, and exchange heat sufficiently with inner the heat flow. In the end, water in the material is dried by repeatedly scattering.

| product standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1-5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6-10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8-15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10-20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12-25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15-30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18-35 | 30% | 15%-1% | 55KW |

| 2.8*26 | 20-40 | 30% | 15%-1% | 75KW |

| 3*28 | 25-50 | 30% | 15%-1% | 90KW |

| 3.2*28 | 30-60 | 30% | 15%-1% | 110KW |

| 3.4*30 | 35-70 | 30% | 15%-1% | 132KW |

| 3.6*32 | 40-80 | 30% | 15%-1% | 160KW |

| 3.8*32 | 50-100 | 30% | 15%-1% | 185KW |