Clay is widely used, mainly used in papermaking, ceramics and refractory materials. Secondly, it is used in coatings, rubber fillers, enamel glazes and white cement raw materials. It is also used in small quantities in plastics, paints, pigments, grinding wheels, pencils, daily cosmetics, soaps, Pesticides, medicines, textiles, petroleum, chemicals, building materials, national defense and other industrial sectors.

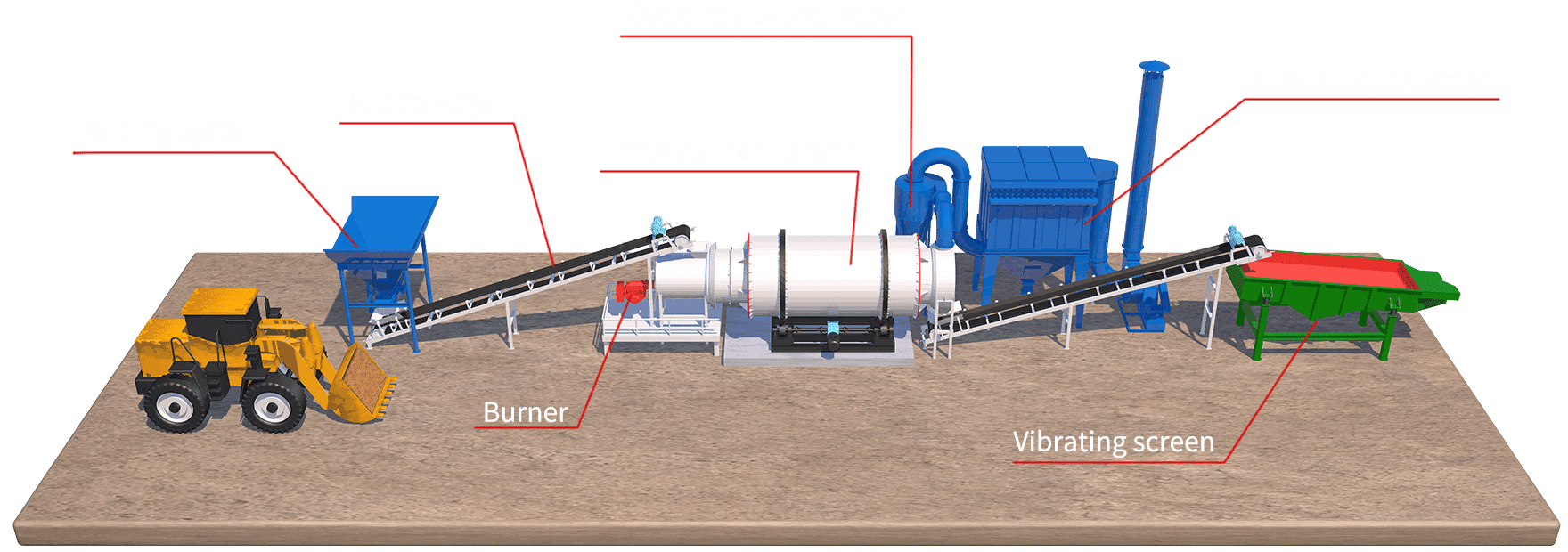

The clay dryer can handle various materials, such as mixed mortar, sand, cement slag, clay, kaolin, Bentonite,gangue, mixture, fly ash, gypsum, iron powder and other raw materials.

| specifications and models | Handling capacity drying sand(t/h) | finished product Moisture(%) | Power(KW) |

| KLF-TH1630 | 1-5 | <2±1 | 4 |

| KLF-TH2240 | 8-10 | <2±1 | 4 |

| KLF-TH2460 | 10-15 | <2±1 | 7.5 |

| KLF-TH2660 | 15-20 | <2±1 | 15 |

| KLF-TH2870 | 25-30 | <2±1 | 18.5 |

| KLF-TH3080 | 30-40 | <2±1 | 22 |

| KLF-TH3290 | 40-50 | <2±1 | 45 |

| KLF-TH3390 | 50-60 | <2±1 | 55 |

| KLF-TH3610 | 70-80 | <2±1 | 75 |

| The above parameters are for reference only. For more details, please contact customer service | |||