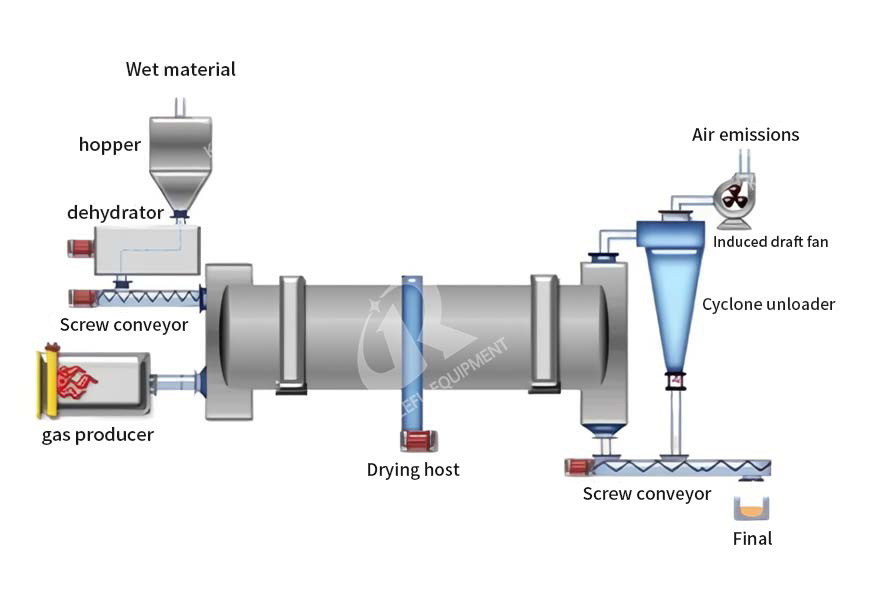

The bean slag is first filtered and dehydrated before entering the dryer. Under the turning of the uniformly distributed shovel plate in the drum, it is evenly dispersed and fully in touch with the hot air in the dryer, which speeds up the heat transfer and mass transfer of the drying. The bean slag is discharged to another discharge valve in the dryer under the action of the inclined shovel plate and the hot medium.

| product standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Power(KW) |

|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | 3KW |

| 1*10 | 1-5 | 30% | 15%-1% | 5.5KW |

| 1.2*12 | 2-8 | 30% | 15%-1% | 11KW |

| 1.6*16 | 6-10 | 30% | 15%-1% | 15KW |

| 1.8*16 | 8-15 | 30% | 15%-1% | 18.5KW |

| 2*18 | 10-20 | 30% | 15%-1% | 22KW |

| 2.2*18 | 12-25 | 30% | 15%-1% | 30KW |

| 2.4*22 | 15-30 | 30% | 15%-1% | 45KW |

| 2.6*24 | 18-35 | 30% | 15%-1% | 55KW |

| 2.8*26 | 20-40 | 30% | 15%-1% | 75KW |

| 3*28 | 25-50 | 30% | 15%-1% | 90KW |

| 3.2*28 | 30-60 | 30% | 15%-1% | 110KW |

| 3.4*30 | 35-70 | 30% | 15%-1% | 132KW |

| 3.6*32 | 40-80 | 30% | 15%-1% | 160KW |

| 3.8*32 | 50-100 | 30% | 15%-1% | 185KW |