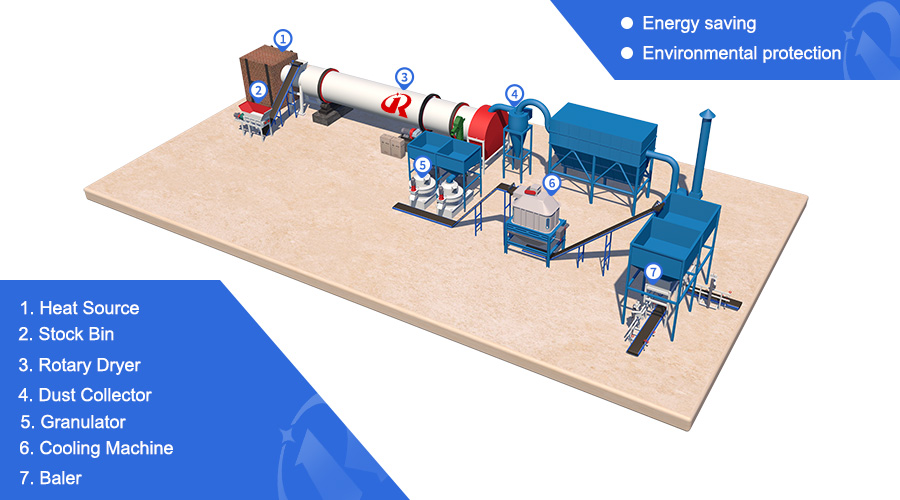

Sugarcane bagasse rotary dryer is a continuous drying equipment widely used in industries such as sugar production, papermaking, and biomass fuel. It is specifically designed to handle high-humidity sugarcane bagasse,drying it to to a lower moisture content (usually 10%-15%) for storage, transportation, or use as boiler fuel, papermaking raw materials, feed raw materials, biomass pellet fuel, etc.

| Model | Input(t/h) | Output(t/h) | Initial Moisture(%) | Final Moisture(%) | Drying Temperature(℃) | Total Power(kW) | Plant Area (m²) |

|---|---|---|---|---|---|---|---|

| KLV-RD10 | 1.8–2.5 | 0.5–0.7 | 45–55 | 10–15 | 250–350 | 25–35 | 75 |

| KLV-RD20 | 2.2–3.2 | 0.8–1.2 | 45–55 | 10–15 | 250–350 | 35–45 | 132 |

| KLV-RD40 | 4.0–5.5 | 1.5–2.0 | 45–55 | 10–15 | 250–350 | 55–75 | 128 |

| KLV-RD50 | 5.0–7.0 | 2.0–3.0 | 45–55 | 10–15 | 250–350 | 75–95 | 144 |

| KLV-RD70 | 7.0–9.0 | 2.5–3.5 | 45–55 | 10–15 | 250–350 | 95–125 | 200 |

| KLV-RD100 | 10.0–14.0 | 4.0–6.0 | 45–55 | 10–15 | 250–350 | 125–155 | 240 |